When selecting cables for electrical systems, two key parameters often come into focus: the cable rating and the cross-sectional area (CSA).

These attributes are deeply intertwined, and understanding their relationship is critical for ensuring the safe, efficient, and long-term operation of electrical systems.

A cable's rating is influenced by several factors, one of the most important being its cross-section.

In this article, we’ll explore the connection between a cable’s rating and its cross-sectional area, focusing on what these terms mean, why they are important, and how they influence one another in practical applications.

A cable's rating refers to the maximum current, voltage, or power that a cable can safely carry under specified conditions. The most common types of cable ratings include:

Current Rating (Ampacity): This is the maximum current (measured in amperes) that a cable can carry without exceeding its temperature limit.

Voltage Rating: The maximum voltage a cable can handle without breaking down electrically.

Power Rating: This refers to the total amount of electrical power (measured in watts or kilowatts) that the cable can safely carry.

These ratings ensure that the cable will function correctly without overheating, causing electrical hazards, or deteriorating over time.

They are determined based on various factors, including the insulation material, ambient temperature, and, crucially, the cross-sectional area of the cable.

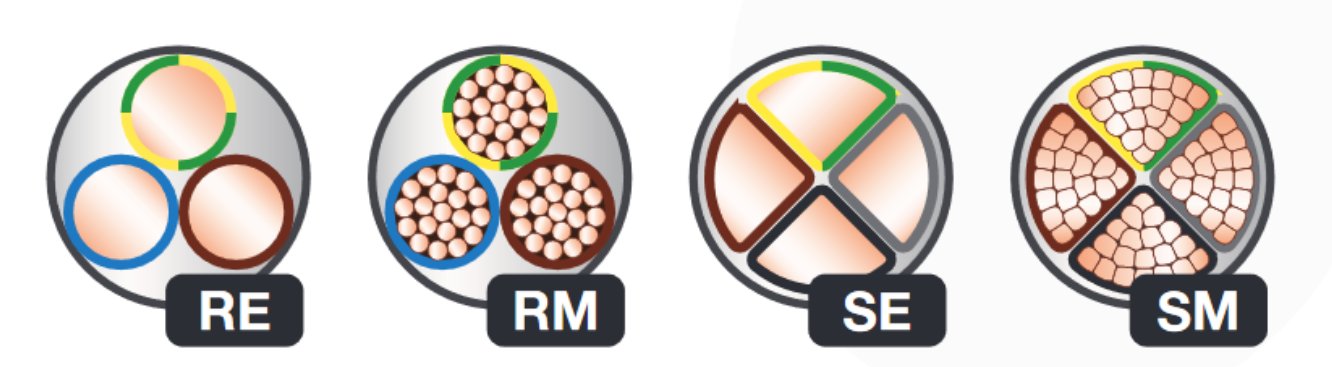

The cross-sectional area (CSA) of a cable refers to the area of its conductor when viewed as a cross-section, typically measured in square millimeters (mm2).

A cable's cross-section determines its ability to carry current, with larger cross-sectional areas being able to carry higher currents due to reduced electrical resistance.

The primary relationship between a cable’s rating and its cross-section is centered on its current-carrying capacity, also known as ampacity.

Ampacity refers to the maximum amount of electrical current that a conductor can carry before its temperature exceeds safe levels.

When a cable has a larger cross-sectional area, it can carry more current without overheating. This is because a thicker conductor has lower electrical resistance.

Resistance is a property of the material that opposes the flow of electric current, causing energy to be dissipated as heat. With lower resistance, less heat is generated, and the cable can handle more current without its temperature rising to dangerous levels.

For example:

A cable with a cross-sectional area of 1 mm2 may be able to carry 10 amps of current.

A cable with a cross-sectional area of 2.5 mm2 can carry significantly more current, perhaps 20-25 amps, depending on other conditions.

Thus, for higher current applications, cables with larger cross-sectional areas are required to prevent excessive heat buildup and potential cable damage.

On the flip side, cables with smaller cross-sectional areas have higher electrical resistance.

This means they will generate more heat when current flows through them, potentially exceeding safe operating temperatures if too much current is applied. Over time, this can lead to insulation breakdown, fire hazards, and electrical failure.

For example, using a cable with a cross-sectional area of 1 mm2 to carry 20 amps (when it is rated for 10 amps) would result in overheating and possibly melting the insulation, posing a significant safety risk.

The relationship between a cable's cross-section and its rating is not limited to current-carrying capacity. It also impacts another key factor: voltage drop.

Voltage drop refers to the reduction in voltage as electricity travels through the cable over a distance. The longer the cable, the more voltage is lost, and this effect is more pronounced with cables that have smaller cross-sectional areas.

The formula gives the voltage drop across a conductor:

Voltage Drop(V)=I×R×Ltext{Voltage Drop} (V) = I times R times LVoltage Drop(V)=I×R×L

Where:

III is the current flowing through the conductor (in amperes),

It is the resistance of the conductor (which is inversely proportional to the cross-sectional area),

It is the length of the conductor.

Cables with a larger cross-sectional area have lower resistance, which helps minimize the voltage drop over long distances. Therefore, in applications where the cable needs to run over long distances, using a cable with a larger cross-section helps maintain a consistent voltage level.

In power transmission systems, where electricity must travel over long distances, cables with large cross-sectional areas are essential to prevent excessive voltage drop. If the voltage drop is too large, the end-users may not receive the correct voltage, leading to inefficient operation of electrical equipment.

While the cross-sectional area plays a critical role in determining the current a cable can handle, it also affects heat dissipation. A larger conductor can dissipate heat more effectively than a smaller one. This is why cables with smaller cross-sectional areas have more stringent installation requirements regarding cooling and ventilation.

The type of insulation material surrounding the cable also affects its rating. Even if two cables have the same cross-sectional area, their ratings can differ based on the insulation material's ability to withstand heat. High-temperature insulation materials allow cables to operate at higher temperatures without degrading, which can increase the current rating for a given cross-sectional area.

For example, a cable insulated with PVC (polyvinyl chloride) will have a lower temperature rating (typically 70°C) compared to one insulated with XLPE (cross-linked polyethylene), which can operate at temperatures up to 90°C.

Therefore, a PVC-insulated cable might have a lower current rating compared to an XLPE-insulated cable of the same cross-sectional area.

In practice, the relationship between cable rating and cross-sectional area is not static, as various environmental and operational conditions can alter the cable's performance. This is where derating factors come into play.

Derating is the process of reducing the current rating of a cable below its maximum capacity, based on conditions such as:

Ambient Temperature: Higher ambient temperatures reduce the cable’s ability to dissipate heat, so the current rating must be lowered.

Installation Method: Cables installed in conduits or trays may not dissipate heat as effectively as those in free air, which affects their current rating.

Grouping: When multiple cables are installed close together, their collective heat output can elevate the temperature, requiring derating to prevent overheating.

The cross-sectional area remains a key factor, but derating ensures that the cable operates safely under real-world conditions.

To determine the appropriate cable size for a specific application, both the current-carrying capacity (ampacity) and voltage drop must be considered. Here’s a basic approach:

Determine the Maximum Current: Identify the maximum current the cable will carry based on the connected electrical devices.

Consider Derating Factors: Account for any derating factors, such as installation conditions or ambient temperature.

Calculate the Cross-Section: Use standardized tables that list the cross-sectional areas of cables for different current ratings and voltage drops to find the correct cable size.

Suppose a circuit requires 30 amps of current and runs for 50 meters. In that case, the required cross-sectional area can be calculated to ensure that both the current-carrying capacity and voltage drop are within acceptable limits.

Based on standardized tables for current rating and voltage drop calculations, a 6 mm2 cable might be required to ensure proper operation.

The connection between a cable's rating and its cross-sectional area is fundamental in electrical design and safety.

A larger cross-sectional area allows the cable to carry more current safely, while a smaller area increases electrical resistance, which can lead to overheating and voltage drop.

Key factors like heat dissipation, insulation type, and derating also play a role in determining the final rating of a cable for a specific application.

Understanding this relationship ensures that engineers and electricians choose cables that meet the demands of the electrical system, prevent hazards, and maintain efficiency.

Ultimately, proper cable selection, factoring in both rating and cross-section, is essential for safe and reliable electrical installations across industries, from residential wiring to large-scale power distribution systems.