The electrical power industry relies heavily on cables for the safe and efficient transfer of electricity, whether in industrial, commercial, or residential applications.

One of the critical considerations in designing or selecting a power cable is its current-carrying capacity, also known as ampacity.

The cable's cross-sectional area plays a fundamental role in determining its ampacity, directly affecting the load the cable can safely handle.

In this article, we'll dive deep into the connection between the cross-section of a power cable and its current-carrying capacity, exploring key factors like resistance, heat dissipation, and voltage drop.

We'll also discuss the importance of selecting the correct cable size for different loads and environments to ensure system safety and efficiency.

The current-carrying capacity of a cable refers to the maximum amount of electrical current it can safely carry without overheating.

When an electric current flows through a conductor, it generates heat due to the material's resistance.

If the cable is overloaded, this heat can build up to dangerous levels, causing damage to the cable insulation, and surrounding materials, and even posing a fire risk.

Therefore, selecting a cable with the appropriate current-carrying capacity is crucial for ensuring the longevity of the electrical system and preventing safety hazards.

Several factors affect a cable's ampacity, but one of the most important is its cross-sectional area.

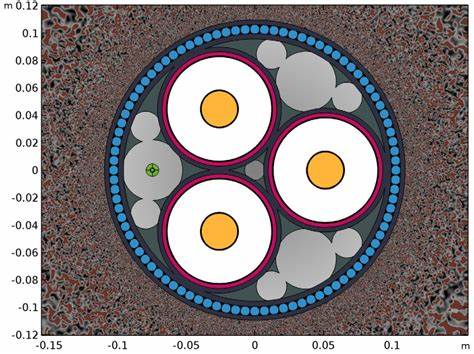

The cross-sectional area of a cable is typically measured in square millimeters (mm2). This area represents the size of the conductor inside the cable, which is usually made from materials like copper or aluminum. A larger cross-section means that there is more conductor material available to carry current, which directly impacts the cable's ability to handle electrical loads.

Here’s why cross-section matters:

Lower Resistance: A larger cross-sectional area reduces the electrical resistance of the conductor. Resistance causes heat generation, and too much heat can lead to cable failure. With a larger cross-section, the current has more pathways to flow through, reducing the overall resistance and minimizing heat buildup.

Improved Heat Dissipation: Cables with larger cross-sections are better able to dissipate heat. Since larger cables have more surface area and mass, they can transfer heat more efficiently to their surroundings, keeping the cable cooler and reducing the risk of overheating.

Voltage Drop Considerations: Voltage drop occurs when voltage is reduced as electric current flows through the cable. This is particularly problematic for long cable runs. A larger cross-sectional area helps reduce voltage drop, ensuring that the electrical equipment receives the required voltage for optimal operation.

The load capacity of a cable is directly related to its cross-sectional area. As the electrical load (measured in amperes, or amps) increases, the current-carrying capacity of the cable must also increase to prevent overheating. Therefore, selecting the correct cross-sectional area based on the expected load is crucial to maintaining the system’s safety and efficiency.

For example:

A small power cable with a cross-sectional area of 1.5 mm2 can handle up to 15-18 amps.

A larger cable with a cross-section of 10 mm2 can handle up to 70 amps.

Extremely large cables, with cross-sectional areas of 240 mm2, can carry currents exceeding 400 amps.

The appropriate cross-section depends on the specific application, including the type of load the cable will carry, the length of the cable, and the environmental conditions in which the cable will operate.

The appropriate cross-sectional area for a specific load can be calculated using industry-standard formulas. One of the most commonly used formulas is:

A=Iκ?SA = frac{I}{kappa cdot S}A=κ?SI

Where:

A is the cross-sectional area of the conductor in mm2.

I is the current carrying capacity (load) in amperes.

κ (kappa) is the conductivity of the conductor material, which depends on whether the cable is made of copper or aluminum.

S is the permissible current density for the material.

In practical terms, when designing or selecting a cable for a specific load, electricians and engineers often consult standardized tables, like those provided by the International Electrotechnical Commission (IEC) or the National Electrical Code (NEC). These tables provide recommended cable sizes for different current loads, accounting for factors like conductor material, insulation type, installation conditions, and the environment.

While the cross-sectional area is a major determinant of a cable’s ampacity, several other factors influence the current-carrying capacity:

Material of the Conductor: Copper and aluminum are the most common conductor materials in power cables. Copper has a higher conductivity than aluminum, which means copper cables can carry more current for the same cross-sectional area. As a result, copper cables are often smaller than aluminum cables for the same load capacity.

Insulation Type: The cable's insulation type affects its heat dissipation capabilities. Some insulation materials can withstand higher temperatures, allowing the cable to carry more current without overheating. For example, cross-linked polyethylene (XLPE) insulation allows higher operating temperatures compared to PVC insulation.

Installation Environment: Environmental factors, such as ambient temperature, the method of cable installation, and whether the cable is installed in a conduit, can all impact the ampacity. For example, cables installed in a hot environment or in tight spaces where heat cannot easily dissipate may need to be derated, requiring larger cross-sections to handle the same load.

Cable Length: For longer cable runs, the voltage drop becomes a significant concern. To counteract this cables with larger cross-sections are used to minimize the voltage drop and ensure efficient power delivery over long distances.

When selecting cables for an electrical system, it is essential to consider both the load and the operating environment. Installing cables with an insufficient cross-sectional area can lead to overheating, increased resistance, and energy loss.

On the other hand, selecting cables with too large a cross-section may result in unnecessary costs, as larger cables are more expensive and harder to install.

Here are some key practical considerations:

Application-Specific Requirements: Different applications require different load capacities. For example, industrial equipment typically demands larger cables than residential wiring due to higher loads.

Code Compliance: Local electrical codes, such as the NEC or IEC standards, provide guidelines for selecting the appropriate cable sizes for various loads. These codes should always be followed to ensure safety and compliance.

Ambient Conditions: The surrounding temperature and installation method (underground, in conduit, exposed, etc.) can affect the cable’s ampacity. Adjustments may need to be made to the cross-sectional area based on these conditions to prevent derating.

Voltage Drop Limits: If a cable run is particularly long, the voltage drop must be calculated and accounted for. To minimize voltage loss, a larger cross-sectional area may be required.

The connection between the cross-sectional area of a power cable and its current-carrying capacity is a fundamental aspect of electrical engineering. The size of the cable directly affects its ability to carry electrical loads safely and efficiently, influencing factors like resistance, heat dissipation, and voltage drop.

Understanding the relationship between a cable’s cross-section and its load capacity allows engineers, electricians, and installers to make informed decisions that ensure system safety, efficiency, and compliance with electrical standards.

By considering factors such as conductor material, insulation type, and installation environment, you can select the right cable size for any electrical application.

Remember, when dealing with the loads of cables, getting the cross-section right is key to optimizing performance and ensuring safety across the board.