ZMS Cable manufacturer is a professional and serious wires and cables manufacturer, with a high reputation all over the world and a positive impact on the international power supply.

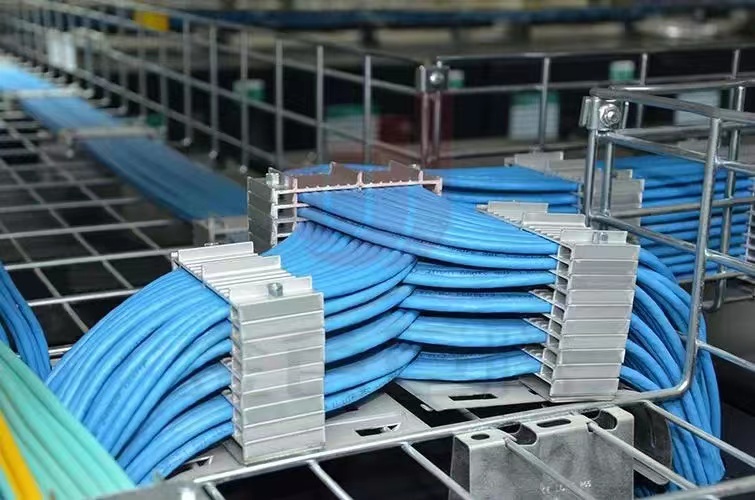

This article is about the inspection procedure for braid.

The procedure is applicable for process inspection of braiding with copper wires, tinned copper wires, Aluminum-magnesium alloy wires, cotton yarn, and other materials.

Any reference documents, just note the date of the applicable version of this document. For undated references, the latest edition (including any amendments) applies to this document.

GB/T 9330.1 PVC insulated control cable, part 1, general regulation.

3.1.1 Wire and diameter should comply with provisions specified in the relevant technical documents.

3.1.2 Braided wires should be free of oil and disordered wire.

The braided density should comply with provisions specified in the relevant technical documents.

The braiding surface should be free of broken wire, jumper wire, oil, or abrasions, and the joints should be trimmed neatly without thread leakage.